WE TRANSFORM YOUR GROWTH STRATEGIES INTO STORE-LEVEL SUCCESS

ABOUT US

GSP provides retail solutions that drive traffic, reduce costs and enhance customer experience. GSP’s AccuStore technology helps retailers target their growth initiatives to the specific needs of each store. Our manufacturing facilities deliver store-specific POP kits to over 75,000 stores monthly. And our Retail Environments supports full-scale store remodels and refreshes for leading brands.

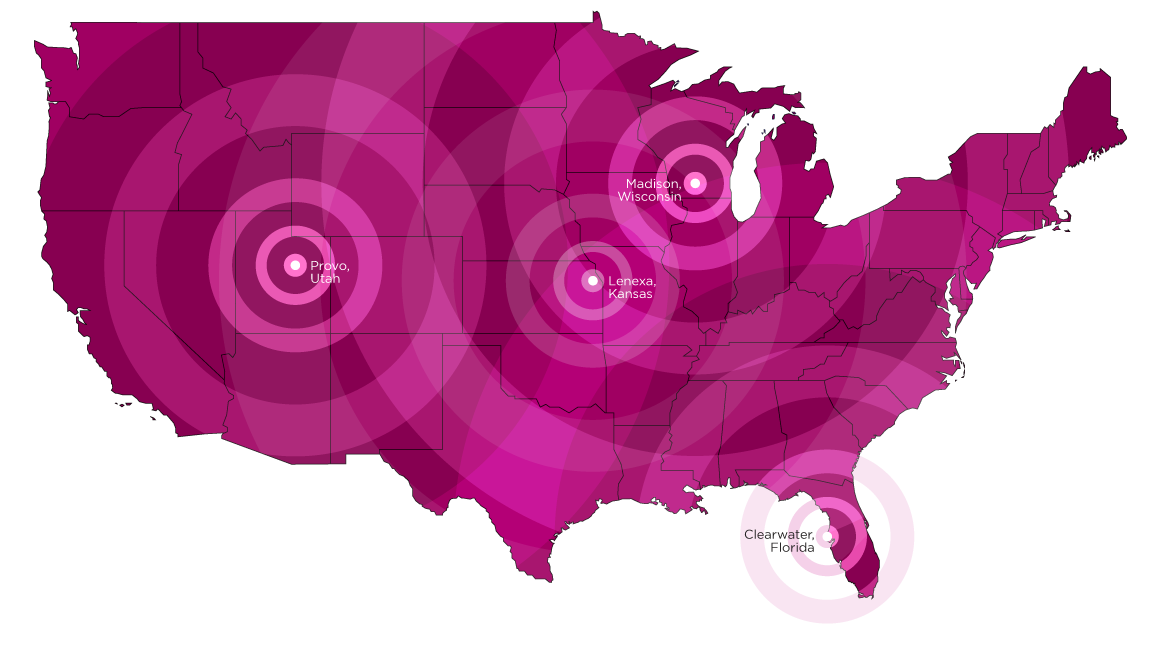

OUR LOCATIONS

Our production and fulfillment facilities operate 24/7 and are placed strategically across the country to increase efficiency and speed to market, while reducing transit times, shipping costs, and carbon footprints.

CONTACT US

GSP Companies Corporate

800.677.0447

14055 46th Street North, Suite 1112

Clearwater, FL 33762

GSP Utah

801.841.4647

1281 South 350 East

Provo, UT 84606

GSP Wisconsin

608.257.7071

5701 Manufacturers Drive

Madison, WI 53704

GSP Kansas

Custom Color Corp

913.730.3100

14320 W. 101st Terrace

Lenexa, KS 66215